Unilever and Genomatica enter €114 million initiative to develop plant-based feedstocks

Unilever and Geno have teamed up on the multi-million-pound deal to develop and launch plant-based alternatives to feedstocks such as palm oil or fossil fuels to produce core ingredients for everyday personal care products.

The duo behind the new initiative, of which Unilever is the first to support through investment, is expecting additional investors to join its goal of establishing sustainably-sourced palm oil in the personal care market. In addition, as part of the initiative, the companies are said to be striving to identify and deliver additional responsibly sourced palm oil alternatives to the industry.

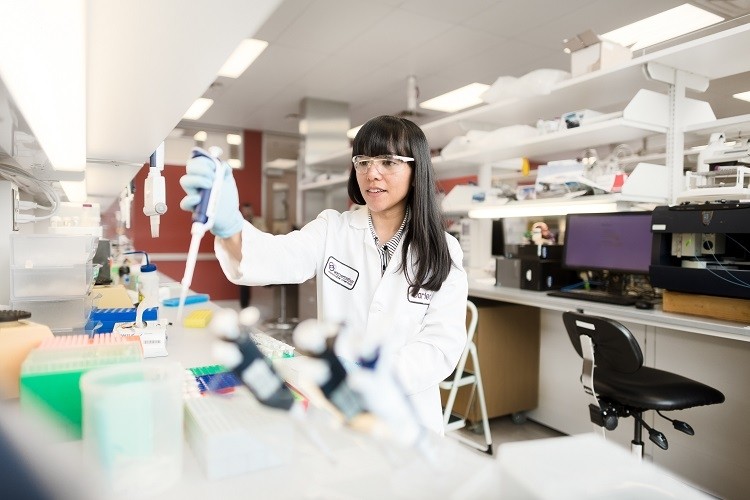

Using biotechnology to find new ingredients

With biotechnology at the centre of the venture, the partnership marks Unilever’s largest investment to date in exploring possible biotechnology alternatives to palm oil. It is understood the initiative will focus on commercialising and scaling alternatives to palm oil and fossil fuel-derived cleansing ingredients by seeking options for prominent ingredients within personal care items that rely on cleansing by lathering and lifting dirt.

Unilever and Geno are said to have recognised the opportunity to fill a sought-after gap for viable sustainable industry alternatives to replace current palm and fossil fuel sources having noted the potential in the combined personal care and home care market, which it shares, is currently valued at €595 billion ($625 bn).

Making its first foray into biotechnology for Unilever comes as beauty and personal care brands turn to science and engineering disciplines to find and produce new varieties for traditionally-sourced ingredients that solve a problem. With an ever-increasing consumer focus on sustainable options, Unilever believes alternative ingredients that focus on protecting the planet can help build sustainability, cost efficiencies and transparency while giving the industry increased options. Unilever have, however, stated that palm oil will remain an important feedstock.

Personal care production seeks supply chain diversification

Speaking to Cosmetics Design Europe on the venture's potential within personal care production, CEO of Geno, Christophe Schilling, said the initiative represented the opportunity to “create additional sustainable sources of palm oil alternatives across the $625 billion home and personal care markets”.

He added: “Our sustainable ingredients and materials will play a growing role in diversifying supply chains to drive optionality, sustainability, cost efficiencies and transparency. Geno’s technology has the potential to reduce greenhouse gas emissions by 100-million tons in upcoming years and at the same time also aims to create more resilient supply chains that are transparent, traceable and responsibly sourced.”

Creating sustainable alternatives

Geno will use its biotechnology platform to explore alternative feedstocks. At present, the company is starting to scale its intended process for its advanced technology to manufacture ingredients. Calculations at this stage indicate that personal care brands may be able to lower palm-derived ingredients' carbon footprint by up to 50% with a commercialised plant-based alternative.

“This new venture will sit at the intersection of science and sustainability, meaning we can continue to grow our business without relying only on palm oil or fossil fuel derivatives, while also making our supply chains more resilient from having access to ingredient alternatives,” said Richard Slater, Chief Research and Development (R&D) Officer at Unilever.

“We are building this innovative new venture to have the scale to drive real impact and change in our industry, helping to reinvent the chemistry of home and personal care products for the 21st Century,” Slater emphasised. “We will be marrying science and nature to make sure there is no trade-off for our consumers between the efficacy and sustainability of their products.”

Geno is developing and scaling sustainable materials derived from plant- or waste-based feedstocks to provide an alternative to fossil fuels. The company achieves this by using biotechnology to convert plant-based raw materials into chemicals featured in common materials.

“We’ve developed our technology in response to our planet’s urgent climate crisis and we’ve proven that biotechnology can replace traditional production methods to produce ingredients with bio-based sources that deliver both high-performance and sustainability, at scale,” said Schilling.

![Many beauty manufacturers and brands have driven green transformations, but suppliers think cost and lack of harmonisation may be slowing wider uptake of ingredients and raw materials [Getty Images]](https://www.cosmeticsdesign-europe.com/var/wrbm_gb_food_pharma/storage/images/_aliases/wrbm_medium/publications/cosmetics/cosmeticsdesign-europe.com/article/2022/12/14/green-beauty-suppliers-say-ingredient-uptake-slow-because-of-cost-and-lack-of-harmonisation/16024649-1-eng-GB/Green-beauty-suppliers-say-ingredient-uptake-slow-because-of-cost-and-lack-of-harmonisation.jpg)

![Unilever has been in global negotiations with retailer partners worldwide on tackling high inflation with price hikes [Getty Images]](https://www.cosmeticsdesign-europe.com/var/wrbm_gb_food_pharma/storage/images/_aliases/wrbm_medium/publications/cosmetics/cosmeticsdesign-europe.com/article/2022/07/27/unilever-q2-h1-financial-results-grow-despite-serious-inflation-pressures/15633027-1-eng-GB/Unilever-Q2-H1-financial-results-grow-despite-serious-inflation-pressures.jpg)

![Unilever wants to develop scalp, oral and underarm care products using 'skin-identical' lipid precursor technology that stimulates natural ceramide production in skin [Getty Images]](https://www.cosmeticsdesign-europe.com/var/wrbm_gb_food_pharma/storage/images/_aliases/wrbm_medium/publications/cosmetics/cosmeticsdesign-europe.com/article/2022/07/20/unilever-to-develop-skin-microbiome-products-in-scalp-oral-and-underarm-care-with-ceramide-technology/15613431-1-eng-GB/Unilever-to-develop-skin-microbiome-products-in-scalp-oral-and-underarm-care-with-ceramide-technology.jpg)

![Chinese study highlights mental health challenges in atopic dermatitis, emphasising holistic patient care. [Getty Images]](https://www.cosmeticsdesign-europe.com/var/wrbm_gb_food_pharma/storage/images/_aliases/wrbm_tiny/publications/cosmetics/cosmeticsdesign-asia.com/headlines/formulation-science/chinese-research-linking-atopic-dermatitis-to-mental-health-underscores-need-for-holistic-care/17040623-1-eng-GB/Chinese-research-linking-atopic-dermatitis-to-mental-health-underscores-need-for-holistic-care.jpg)