Promotional Features

Starch: the alternative to talc and microplastics for sensory enhancement

For over a century, talc, otherwise known as hydrated magnesium silicate, was used to provide softness and absorption in cosmetic and personal care products at a low cost. However, “talc-free” claims have become the new buzz in the beauty industry, largely stemming from recent FDA advisory notices that some talc products have been found to be contaminated with asbestos and lawsuits related to alleged links between talc and cancer.1 This trend has forced the industry to look for new alternatives that can provide the functionality of talc without concerns about asbestos.

Meanwhile, sensory enhancing microplastics such as PMMA and Nylon-11 have come under attack as harmful to the environment. Manufactured from petrochemicals such methyl methacrylate acid or polyester, these petro-based plastics are under global regulatory discussion because of their non-biodegradable properties and impact to water resources and aquatic species. Over 20 years, an estimated 500,000 tonnes of microplastics would be prevented from entering our ocean if microplastics would be banned as personal care ingredients.

Safer and more sustainable alternatives are quickly being evaluated to maintain performance and cost with minimal impact to the personal care industry and its customers. Native and modified starches are considered some of the top alternative solutions. Cargill Beauty’s debut into the personal care industry creates a renewable and cost-comparable answer to an unforecasted formulation problem. Cargill sources corn from non-genetically modified crops² as part of the Waxy Corn Promise where EU farmers harvest and manage corn crops to meet the third-party standards of the SAI (Sustainable Agriculture Initiative) platform. Native and modified starches are then produced for use in personal care applications such as color cosmetics, baby powder, APDO and skin care.

Cargill’s Waxy Corn Promise provides transparency to the source of these starches at a cost that is affordable and without substantial cost increase. Our global innovation team can support reformulation in all beauty care applications.

StarDesign 05340, aluminum starch octenylsuccinate, could offer an immediate solution to formulators with enhanced market benefit. With high oil and water absorption and an average particle size of 10 microns, this biodegradable (According to OECD 301B) product is suitable for vegan, and Kosher and Halal certified. And its spherical shape lends a soft sensory.

StarDesign™ 05340, magnified 100 X

This soft sensory is beneficial in applications where powdery after-feel is desired. Originating from zea mays kernels (maize), which are polysaccharide granules extracted from corn, the modification with n-octenysuccinyl (n-OSA) group through esterification transforms them into sensory enhancers as they become more hydrophobic and oil-absorbing. In emulsion, n-OSA starches reduce the perceived oiliness and the tackiness while giving the skin a powdered and matte-finish.

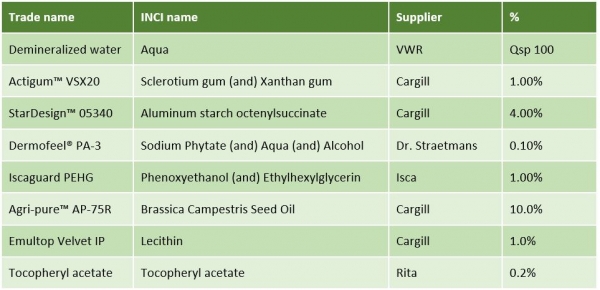

In a standard emulsion, only 4% is needed to give a soft powdery after-feel. In a sensory test of 28 people, the emulsion with StarDesign™ 05340 reduced stickiness and greasiness, and also improved smoothness and penetration.

Cargill Beauty also offers native starches sourced locally from the regions in which they are sold. In Brazil, our native corn starch Amilogill 15210 offers a low micro specification and has been used to replace nonrenewable sensory enhancers in applications across skin care, including body care and APDO.

With consumers looking for sustainable solutions that they trust as safe, Cargill Beauty offers formulators modified and native starch products that are renewable, cost effective and biodegradable. They can replace many of the sensory enhancers traditionally used in makeup, skin care or APDO. Our global team of experts can recommend a product to fit most applications.

Dosage Recommendations by application - StarDesign™ 05340 (Aluminum Starch Octenylsuccinate)

Powder Eyeshadow |

10-20% | Extra Soft Feel, Touch, Absorbency |

Cream to Powder Makeup |

5-10% | Extra Soft Feel, Touch, Absorbency |

Lipstick | 1-5% | Glide & Smooth Application |

Face & Body Cream |

1-3% | Reduce greasiness, Mattifying Effect |

Sources:

1) Reuters https://www.reuters.com/investigates/special-report/johnsonandjohnson-cancer/

2) Cosmetic Business -https://cosmeticsbusiness.com/news/article_page/Europes_microplastics_phase-out_SEAC_draft_opinion_on_restrictions_open_for_consultation/167263

[1] Information on FDA’s research on talc is available here: https://www.fda.gov/cosmetics/cosmetic-ingredients/talc. Example article on lawsuits available here: https://www.reuters.com/investigates/special-report/johnsonandjohnson-cancer/

[2] Current European law with respect to the control and use of genetically modified cereals is laid down by regulation (EC) n°1829/2003 and regulation (EC) n°1830/2003. These Regulations are concerning respectively the traceability and labelling of genetically modified organisms and the traceability of food and feed products produced from genetically modified organisms.

In common with the Starch Europe “purchase protocol” Cargill has instituted detailed procedures to ensure that only conventional maize is processed at its European facilities. These procedures, which have been elaborated in close cooperation with audited, reputable suppliers, stipulate the planting of conventional maize varieties. These procedures include PCR (Polymerase Chain Reaction – the recognized global standard) analysis at an established independent laboratory.

Cargill has established an Identity Preservation System (IPS) as a production method to assure that raw materials containing gene modified maize seeds above the 0.9% threshold established by the above regulations will not enter the production process. This IPS system is evaluated every year by an independent third party, Lloyd’s Register Quality Assurance, who provides a statement of conformity.

Consequently, our maize based products do not require GM labelling according to European Regulation 1829/2003 and 1830/2003